The T7EE T7EDS 062 B31 1R00 A100 hydraulic pump belongs to the vane pump category, which is known for its simplicity, compactness, and high performance.

Vane pumps operate by using rotating vanes to trap and transport fluid through the pump, creating a consistent flow of hydraulic fluid. This type of pump is widely used in applications that require medium to high pressure and a steady flow rate.

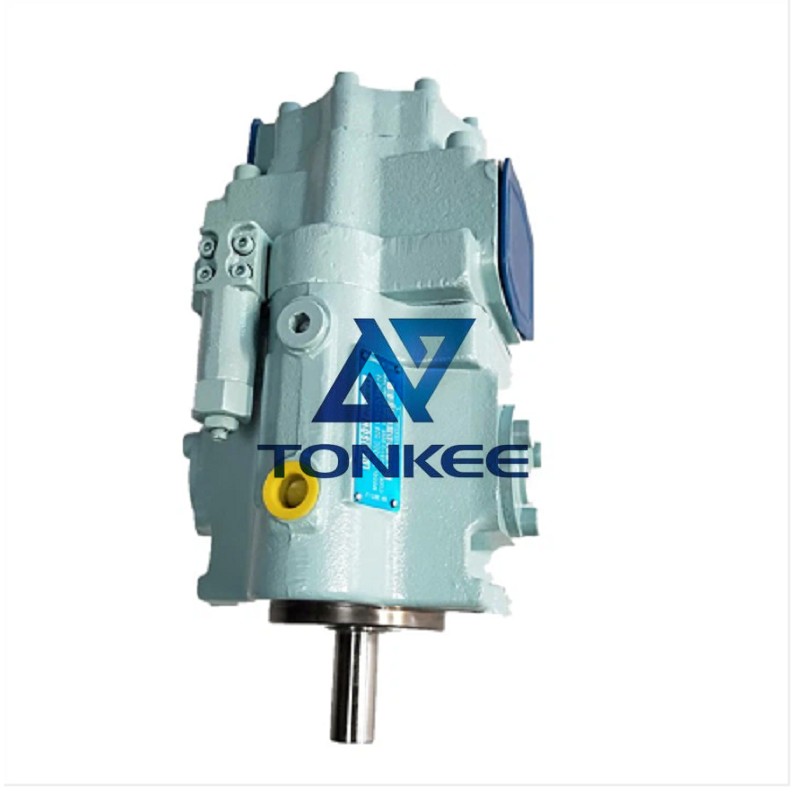

One of the notable features of the T7EE T7EDS 062 B31 1R00 A100 pump is its compact design. This allows for easy installation and integration into hydraulic systems with limited space. Despite its small size, the pump offers a robust performance, making it suitable for demanding industrial environments.

The pump is designed for a maximum operating pressure of 250 bar, providing sufficient power for a range of hydraulic applications. It has a displacement of 62 cc per revolution, indicating the volume of fluid it can deliver per revolution of the pump shaft. This displacement value determines the flow rate of the pump and can be adjusted by varying the rotational speed.

The T7EE T7EDS 062 B31 1R00 A100 pump is known for its high efficiency, which is crucial for minimizing energy consumption and maximizing the overall performance of the hydraulic system. The pump achieves this efficiency through advanced design features, such as precision-machined components and tight tolerances, which reduce internal leakage and optimize fluid flow.

To ensure durability and longevity, the pump is constructed from high-quality materials that are resistant to wear, corrosion, and contamination.

This enhances the reliability of the pump, reducing the risk of downtime and maintenance requirements. Additionally, the pump incorporates a robust sealing system to prevent fluid leakage, ensuring the integrity of the hydraulic system.

The T7EE T7EDS 062 B31 1R00 A100 pump is designed for compatibility with various hydraulic fluids, including mineral oils, synthetic fluids, and biodegradable fluids. This versatility allows it to be used in a wide range of applications and industries, from construction and agriculture to manufacturing and marine.

In terms of installation and maintenance, the pump is user-friendly and requires minimal effort. It can be easily mounted and connected to the hydraulic system using standard fittings and connections. Routine maintenance tasks, such as changing the fluid and inspecting the pump's components, can be carried out efficiently, ensuring optimal performance and extending the pump's service life.